CryoMode delivers chemical‑free, environmentally smart cleaning solutions focused on aerospace, automotive, fleets, food & beverage processors, coffee roasting, military equipment and heavy industrial operations.

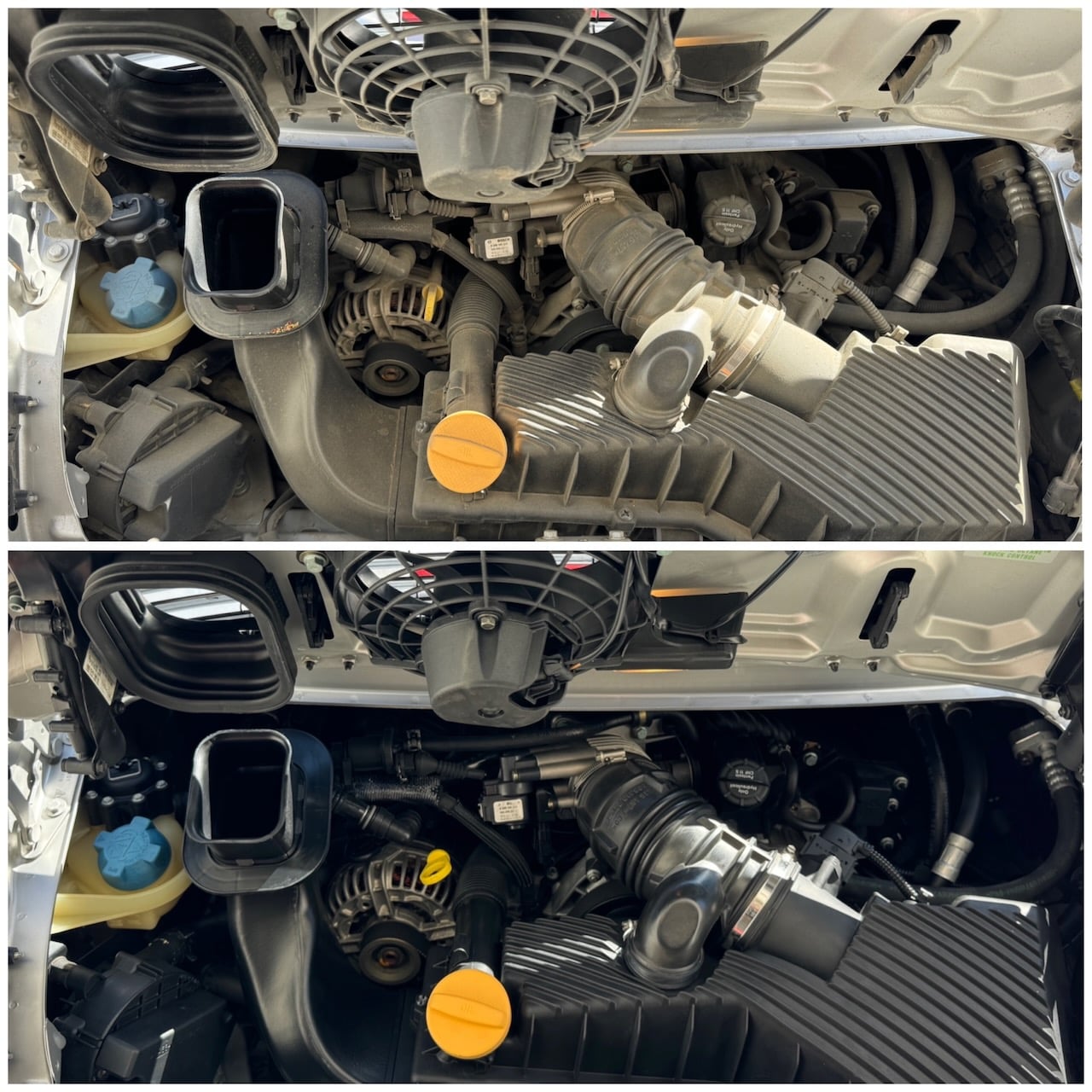

Dry ice blasting is an advanced cleaning process that uses solid CO₂ pellets accelerated at high speeds to remove surface contaminants. Unlike sandblasting or chemical cleaning, dry ice blasting is non-abrasive, non-toxic, and leaves zero secondary waste.

When the pellets hit a surface, they instantly sublimate; turning from solid to gas and lifting dirt, grease, oil, paint, mold plus other build-up without damaging the substrate. Because it’s dry, it’s safe for electronics, motors, wiring, food-grade surfaces, and sensitive aerospace components.

Learn more about how dry ice blasting can help you today.

Laser ablation is a next-generation, contact-free method of removing rust, paint, oxidation, carbon deposits, and surface contaminants using high-powered pulsed lasers. It works by sending focused energy into a targeted layer—vaporizing contaminants without damaging the material underneath.

Unlike traditional blasting or chemical stripping, laser ablation is dry, non-abrasive, and produces minimal waste. It’s safe for use on delicate substrates such as aerospace alloys, stainless steel, anodized parts, and historic surfaces. There’s no media to dispose of, no masking, and no chemical runoff—just clean, controlled, precision surface prep.

CryoMode uses Class IV industrial laser ablation systems to deliver pinpoint control and repeatable results across aerospace, manufacturing, restoration, and maintenance projects.

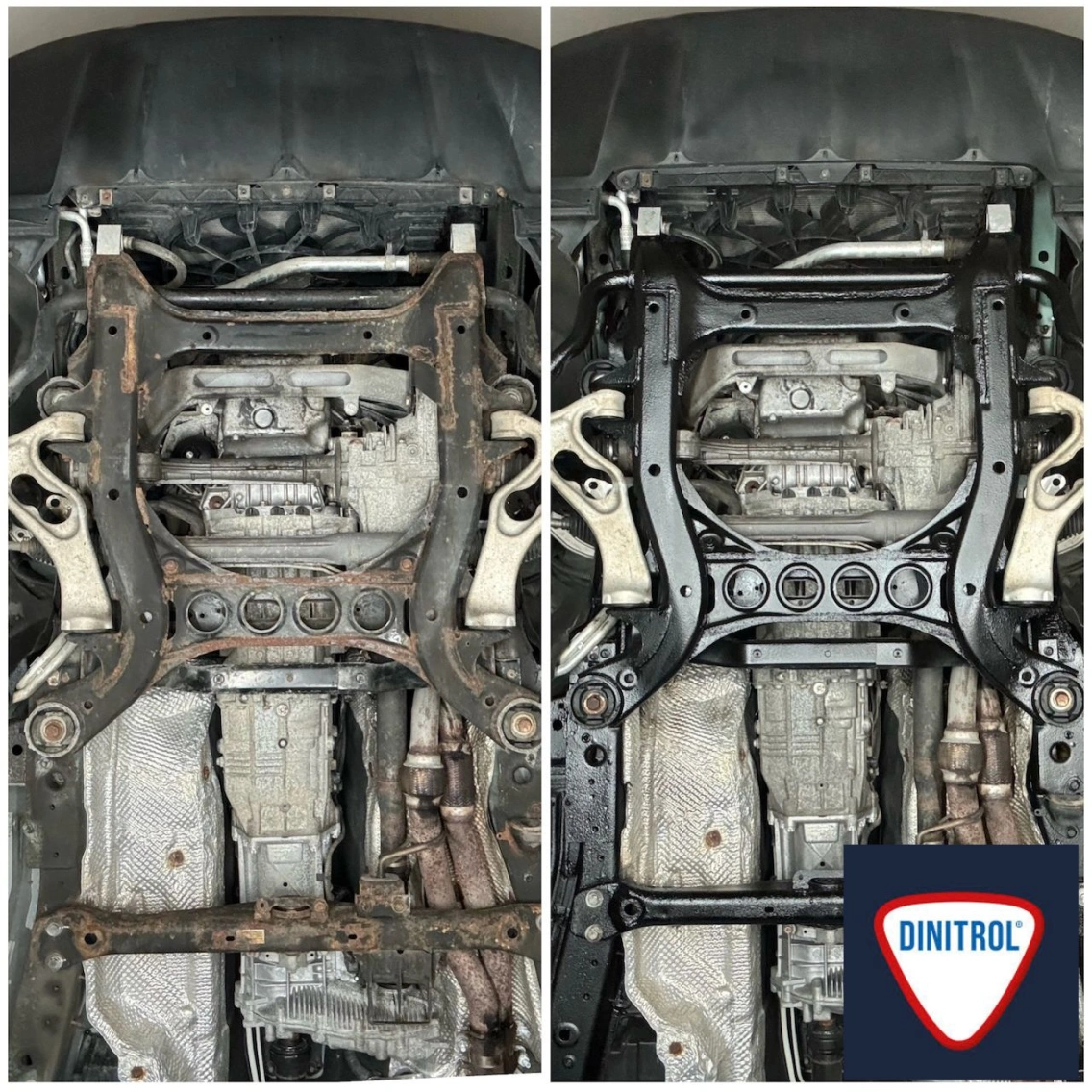

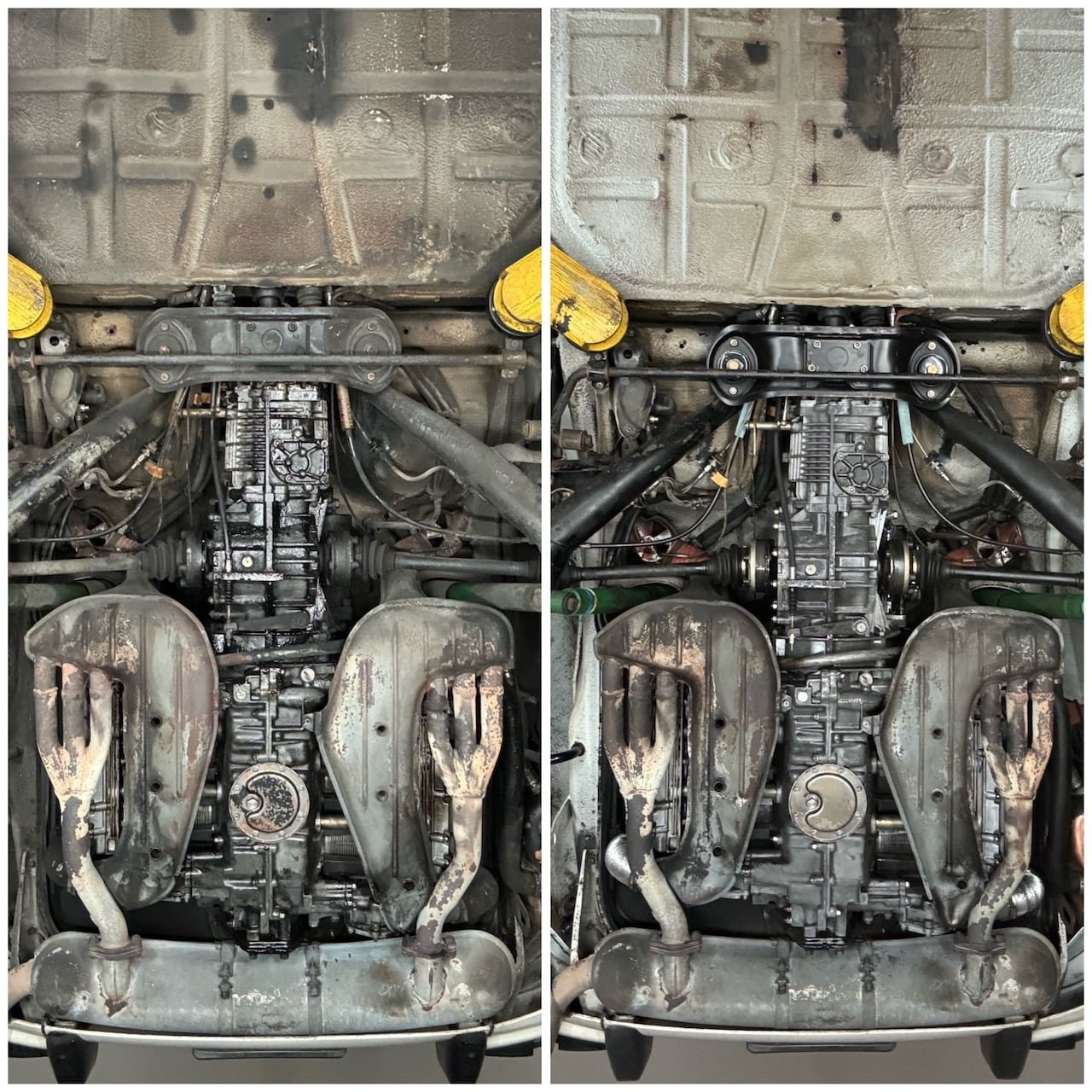

Vehicle undercoating is the process of protecting a car’s underside from rust, corrosion, and road wear—especially critical for classic, exotic, and collector vehicles where factory originality and long-term preservation matter most.

At CryoMode, we take a non-invasive approach using dry ice blasting to remove years of grime, factory cosmoline, surface rust, oil, and road debris without damaging original finishes, welds, or components. There’s no water, no abrasives, and no harsh chemicals—just clean, pressurized CO₂ that sublimates on contact.

Once the surface is fully restored, we apply a high-performance ceramic-based undercoating that bonds with the metal to create a durable, hydrophobic barrier—resisting moisture, salt, and debris while maintaining a clean, detailed appearance. This is not bedliner or rubberized spray—this is a purpose-built protection system that complements the care and value of specialty vehicles.

Do you want to learn more about how vehicle undercoating can prevent rust for your vehicle.

Routinely cleaned equipment lasts longer and works better. Our dry ice blasting uses reclaimed CO₂ pellets that sublimate on impact, leaving no secondary waste, no abrasive wear, and no moisture.

Laser Ablation adds precision to delicate surfaces, eliminating oxide, coatings, and built‑up carbon without tooling damage. The result: faster turnaround, lower disposal costs, extended asset life, and safer, greener operations.

We stand by our workmanship and provide a satisfaction guarantee. To learn more or receive your free evaluation, please click below